Table of contents

When it comes to retail-related acronyms, SKU is likely one you’ve heard a million times, but you may not know the meaning.

SKU stands for ‘stock keeping unit’ and, as the name suggests, it’s a number (usually eight alphanumeric digits) that retailers assign to products to keep track of stock internally. If a product has different colours and sizes, each variation has a unique SKU number.

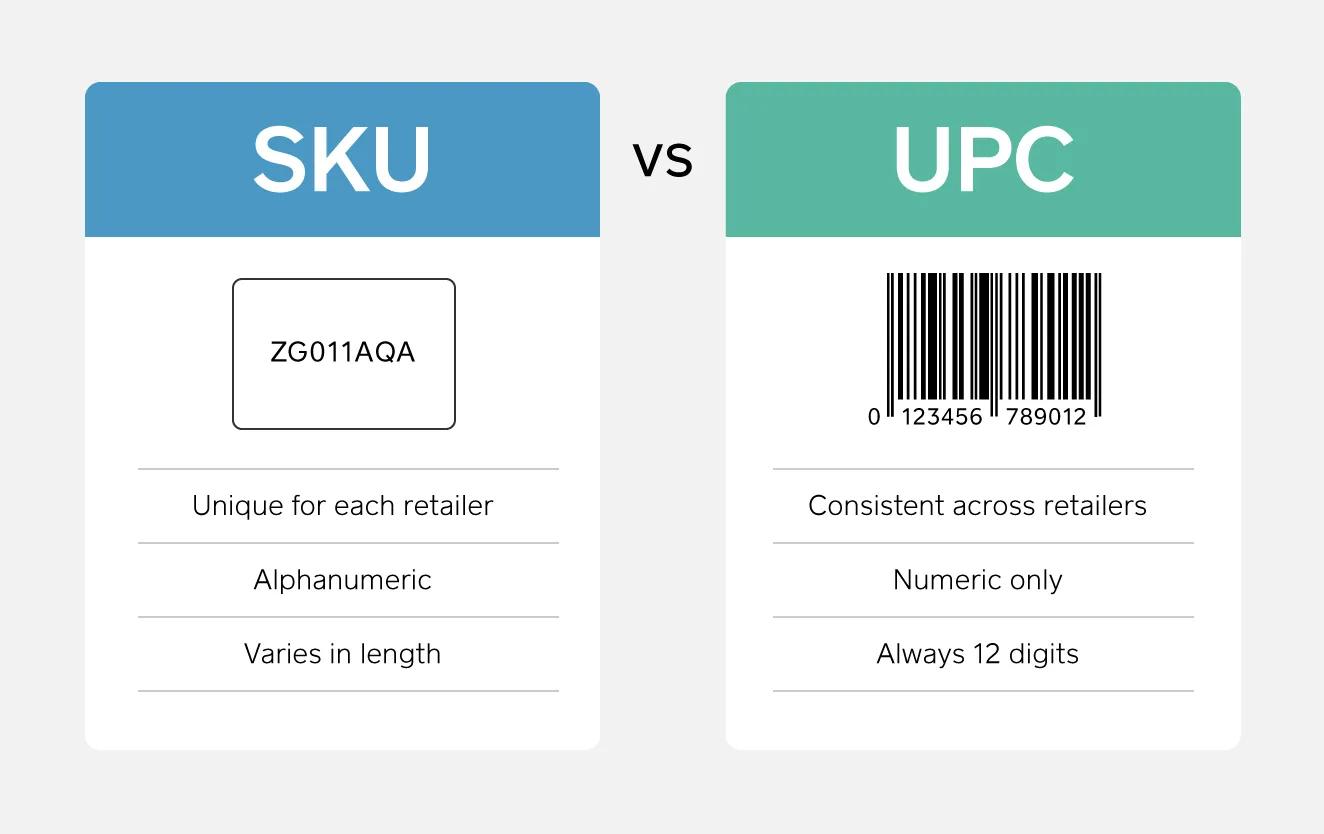

SKUs versus UPC codes

You may have heard SKU and UPC used interchangeably. They are similar but serve different purposes for in-store and online retailers.

A UPC, or universal product code, is a 12-digit numeric code that’s attached to products wherever they are sold for external use. It’s often referred to as a ‘UPC code’, which awkwardly translates to ‘universal product code code’.

A product has the same UPC no matter where it’s sold, but different stores assign it different SKUs – that’s because SKUs are typically unique to a single retailer. However, there are a lot of retailers that use UPCs as SKUs. Smaller shops (especially those that make their own products) may find it beneficial to create their own SKU system.

SKU management

If you’re going to use SKUs, their management is incredibly important. SKU management allows you to analyse the cost of carrying each product, so you can be sure that every piece of inventory meets the financial objectives of the business.

When done well, SKU management allows you to optimise inventory levels and purchasing (and increase revenue). You’ll have high inventory holding costs and less available capital if done poorly.

Here are the best practices to follow when creating SKUs:

- Each SKU should be unique for accurate inventory tracking. Avoid duplicate SKUs, even if it’s a variation of the same product.

- Do not use special characters or punctuation; only use numbers and letters from the Roman alphabet.

- Keep it concise and logical. The first few letters should represent the highest category of importance, depending on your business (for example, brand, make, then model).

- Start with a letter. This can help employees identify product categories.

- Maintain consistency in your SKU format across all products to streamline your inventory management. This makes it easier for employees to understand and manage the SKUs.

- Periodically review and update your SKU system to ensure it remains relevant and efficient, especially as your product assortments evolve.

You can manage SKUs manually or take an automated approach:

Manual SKU management

If you go the manual route, you need to calculate two metrics – SKU ratio and sales ratio – and then compare them.

- Calculating SKU ratio: Start by looking at your product catalogue and making a list of all your SKUs in a spreadsheet. For each SKU, note the price, how much it cost you and the gross profit. (Subtract your cost from the price to determine your gross profit.)

Next, create gross profit ranges in your spreadsheet (less than £20, £20–£29.99, etc.) and note how many SKUs fall in each range. Divide the number of SKUs in a range by the number of total SKUs (and multiply by 100) to get your SKU ratio for each range.

- Calculating sales ratio: Using the same gross profit ranges, note the number of units sold (in a given time). Then divide the number of units sold in each gross profit range by the total units sold (and multiply by 100) to get the sales ratio for each range.

- Examining your findings: In a spreadsheet, compare the SKU ratio and sales ratio of each gross profit range. If you’re more of a visual person, you can plot this information on a graph to see how your SKU ratio compares to your sales ratio.

Your best-performing products fall in the gross profit range with a sales ratio that’s significantly higher than the SKU ratio. It means there’s high demand for those products and the potential for generating more sales if you increase inventory or marketing.

Is the SKU ratio higher than your sales ratio in the gross profit range? Those are your worst performers. It means there is too much supply, and you should reduce inventory and marketing (or even stop selling the products).

Automated SKU management

The process of manually managing SKUs may seem a little tedious, but don’t worry, you can automate SKU management. Automating your SKU analysis reduces costs and improves the accuracy of your data.

You can automate the process by leveraging POS systems with integrated inventory management and other tools like barcoding. Using software to manage your inventory allows you to electronically track items in real time, and automatically update inventory. In addition, built-in analytics help you create more efficient purchasing processes and more effective sales and marketing strategies.

The benefits of using SKUs to manage your business

SKUs provide insight into your business’s lifeblood – your inventory. So it’s no surprise that using SKUs properly can benefit businesses immensely when it comes to inventory management, customer experience, and even supply chain management.

Here are the top ways managing your SKUs, with the right technology, can improve operations and customer satisfaction.

Using SKUs for inventory management

SKUs are typically the easiest way to track an item’s availability across all locations, whether in person or online. Managing your SKUs with an intuitive point-of-sale (POS) system, like Square Point of Sale, gives businesses a line of sight into how products are moving across all locations.

When you know how your products are selling (or not selling), you can make informed decisions on when to run a discount, move inventory between store locations, and reorder products from suppliers. Investing in a POS system that automatically syncs inventory and sales data using SKUs will help you make business decisions using real-time insights before running out of stock or offering an unnecessary discount.

SKUs can even improve the customer experience. Using SKUs to track stock can improve your inventory buying and help employees better serve customers. An intuitive and well-organised SKU management system enables staff to look up product information quickly and accurately to answer customer questions on the spot. For example, if a customer visits a store in person and the sweater size they want isn’t in stock at that location, you can have them order online or visit a nearby store where it is in stock.

Providing customers with the information they need quickly can help build brand loyalists.

Forecasting sales and optimising your supply chain with SKUs

Just like managing SKUs well gives you a better shot at nailing inventory management, it can also improve your demand forecasting – the ability to accurately predict what customers will buy and in what quantities throughout the year. Developing an accurate demand forecast will help avoid understocking and missing out on sales, or overstocking and carrying unwanted inventory liability.

By using SKUs to get a clear picture of your available stock and sell-through patterns by product and product category, it’s easier to predict sales patterns. When you’re able to forecast your sales demand accurately, it enables buyers to work with suppliers with enough advanced notice to secure the products required to maximise sales, typically at a better rate.

Analysing your SKU-level inventory and sales data using vendor sales, projected profit and sell-through reports available with Square Point of Sale is easy. It also provides the information businesses need to negotiate favourable supplier agreements and predict sales demand with better accuracy, ultimately reducing inventory liability.

Managing SKU numbers with Square Point of Sale

You can use Square Point of Sale to print labels for all your products that include a SKU.

If you don’t yet have one, devise an easily decipherable code for generating SKUs, referencing information like the type of item, size, colour, brand, etc. If you’re not interested in creating your own system, try a SKU generator.

In your Square Point of Sale point of sale, start logging your products in your Square Dashboard. To enter a new product, click Create Item in the top-right corner. Next, fill in the item information (including SKU number), upload a photo and add the variation information, like price, size, and number of items in stock.

After you’ve added everything to your Dashboard, you can organise your inventory by creating various categories, like jewellery, shoes, and clothing. Then, add products to categories by clicking Assign Item and checking the appropriate boxes. You can also use your Dashboard to delete items. If you have multiple locations, keep in mind that employees can only edit variation prices at the locations where they have access.

Once you’ve added items, go to the Inventory Management section of your Dashboard. Then click Stock > Print Labels. Learn more about printing labels in our Support Centre.

Don’t need these advanced inventory features? Square Point of Sale, our free POS app, includes free inventory management software built for smaller businesses. Read more about how Square compares with Shopify and other POS systems.

![]()